CFD Research, in collaboration with Stanford University, recently won a $750k Small Business Technology Transfer (STTR) contract from the U.S. Navy to develop physics-based computationally efficient models for multiphase combustion. The Navy recognizes that accurate modeling of underlying physical processes, involving the evaporation of fuels, preferential vaporization, mixing and ignition is an important challenge for the reliable prediction of liquid fuel effects on the combustion in aviation combustors and augmentors.

“A complicating factor is the fact that aviation fuels relevant for Navy and other DoD components contain multiple components and the evaporation of corresponding fuel droplets cannot accurately be described using an effective single component or surrogate representation,” said Dr. Ranjan Mehta, CFD Research Principal Investigator.

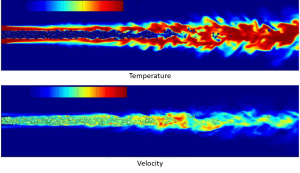

In prior work, a simple mixture-fraction based combustion model was demonstrated and evaluated for Navy-relevant aviation fuels. The key shortcomings of the models were identified by comparison with appropriate Direct Numerical Simulation data and available experiments. In this follow-on project, the spray combustion models will be advanced to include other key physical processes such as spray atomization, interaction with turbulence, preferential evaporation, and the coupling with other CFD codes. The result will be a well-validated multiphase combustion model available to the Navy, its contractors and U.S. industry.

In prior work, a simple mixture-fraction based combustion model was demonstrated and evaluated for Navy-relevant aviation fuels. The key shortcomings of the models were identified by comparison with appropriate Direct Numerical Simulation data and available experiments. In this follow-on project, the spray combustion models will be advanced to include other key physical processes such as spray atomization, interaction with turbulence, preferential evaporation, and the coupling with other CFD codes. The result will be a well-validated multiphase combustion model available to the Navy, its contractors and U.S. industry.

The technology will facilitate significant advancements in spray combustion capabilities, allowing improved and computationally efficient predictions of atomization, evaporation, spray/flame coupling, and combustion stability characteristics including those for aero engine augmentors, internal combustion engines, and other combustion devices.

“The software will provide significant value to OEMs such as Rolls Royce, GE Aviation, Pratt & Whitney, and Williams International to assist in design, analysis, performance and operability of various gas turbine combustor systems and components. It will be a valuable tool for all industries that require CFD simulation of reacting flows,” said Sami Habchi, CFD Research executive vice president.

About CFD Research:

Since its inception in 1987, CFD Research has worked with government agencies, businesses and academia to provide innovative solutions within the Aerospace & Defense, Biomedical & Life Sciences, and Energy & Materials industries. Over the years CFD Research has earned multiple national awards for successful application and commercialization of innovative component/system technology prototypes, multi-physics simulation software, multi-disciplinary analyses, and expert support services. CFD Research is an ISO9001 and AS9100 registered company and is appraised at CMMI Level II for services. Learn more at www.cfdrc.com.