Huntsville, Ala. | November 20, 2019 – CFD Research Corporation, in collaboration with the University of Connecticut, University of Illinois-Chicago and Prof. Hai Wang were recently awarded a $750k Small Business Technology Transfer (STTR) contract from the U.S. Air Force Office of Scientific Research (AFOSR) to develop a physics-based modeling framework specifically for the challenges of simulating high-pressure turbulent combustion in the distributed combustion regime. The resulting tools and datasets will enable analysis of the effects of a wider range of high turbulent conditions that are present in devices including liquid rocket engines, rotating detonation rocket engines, and scramjet combustors.

“A major fundamental research challenge is the lack of quantitative understanding on the impact of turbulence on the chemical reaction pathways in the small molecule foundational chemical kinetics mechanisms at high-pressure distributed reaction regime,” said Dr. Ragini Acharya, CFD Research Director and Principal Investigator for the project.

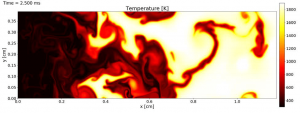

Instantaneous temperature contour from Flame Brush simulation.

In prior work, the team performed the first known sensitivity calculations of the HyChem chemistry model for combustion of Jet A fuel with air by using a novel two-dimensional direct numerical simulation approach. The team recommended a number of elementary reactions that could affect a reliable prediction for the high-pressure turbulent combustion.

In this follow-on effort, the framework will be further developed for a wider range of high turbulence conditions. Sensitivity analyses of the foundational chemistry model will be performed with this framework under a wider range of relevant conditions. Recommendations from these analyses will lead to the execution of a number of high-pressure shock tube experiments and ab-initio calculations to validate and improve the models.

“The technology is directly relevant to the research conducted by the Air Force on very high-pressure highly turbulent reacting flows relevant to a multitude of high-speed propulsion technologies for military applications,” said Dr. Scott Miller, CFD Research Vice-President for Energy and Propulsion. “It will be a valuable tool for all industries that require CFD simulation of reacting flows.”

The primary customers for the proposed technology and related adaptation, customization and application services include government organizations, prime contractors, and national laboratories that are involved in the design, development, and performance analysis of propulsion technologies.

About CFD Research: Since its inception in 1987, CFD Research has worked with government agencies, businesses and academia to provide innovative solutions within the Aerospace & Defense, Biomedical & Life Sciences, and Energy & Materials industries. Over the years CFD Research has earned multiple national awards for successful application and commercialization of innovative component/system technology prototypes, multi-physics simulation software, multi-disciplinary analyses, and expert support services. CFD Research is an ISO9001 and AS9100 registered company and is appraised at CMMI Level II for services. Learn more at www.cfdrc.com.